Top 3 Questions to Ask and Details to Consider When Moving Tools

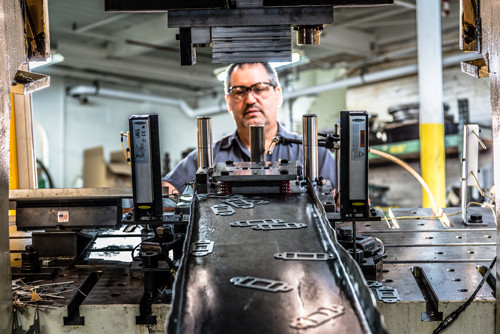

Here’s a reality we hope you haven’t experienced: your sizeable investment in tooling has been rendered unproductive due to changing circumstances with your metal stamping vendor. Because your metal stamping die depends on a cooperative and competent supplier to produce good parts, there is much to consider in this situation.

Three questions off the top:

Three questions off the top:

- How do you know when is it time to move your tool?

- What do you look for in a new vendor?

- What information does that new vendor need to assess whether you are a good fit for each other?

1) Time to Change Your Tool

Let’s tackle the fundamental question here: how do you know when it is time to move your tool? There are some indicators that will signal it may be time for a change.

Quality problems. You may find you are having issues with good quality stamping, which is compromising the quality and performance of your product. This is a solid indication that you need to look at your tooling as a potential cause. If your current vendor is not able or willing to resolve the quality issues, it’s time to find a vendor that is. Keep in mind: your quality problems may be built into the tool or process. You can’t take that tool to a new vendor and expect all quality problems to go away. Moving to another vendor may also require re-working the tool to remedy quality problems, so this needs to be part of the process when considering moving your tool to improve quality.

Vendor out of business. Yes, it happens. And quite simply, you are forced into finding a new vendor. Hopefully, you have been given fair warning of an impending closure, and your old vendor is willing to cooperate with you in releasing the tooling. The best vendors will even work with your new vendor to transition the tooling to its new home, and it may be worth any reasonable charge they may quote for their services.

Run quantity decrease. It’s common when running legacy parts for production runs to decrease over time. If you are at the point that the runs have gotten so low that your vendor (geared for higher production outputs) doesn’t want to carry you as a customer, it’s time to get a new production partner.

Culture clash. In this scenario, you are at the wrong end of the equation when your vendor feels that you just aren’t a good fit anymore. The vendor might have changed focus (working more with OEM products), been bought out by a competitor, or is unwilling to conform to certain quality standards. These could result in general cooperation issues or production problems, but either way, it leaves you looking for another vendor.

2) Looking for a New Metal Stamping Vendor

What do you look for in a new vendor, and what do you need to consider during this process? Here are the questions and consideration that should be part of your selection process.

Shop around. This is not something you do on a whim. You need to shop around, but not just for the best price or the quickest fix. Look at the elements that are on the list above, and take all these possible scenarios into account. Picture you and your business facing them at any time in your relationship with your production partner. Might any of these be potential issues for you and the vendor? Gauge these as risks and decide how good the fit might be.

How invested are they, literally? Contracting with a vendor to build and run tooling to produce your metal stampings means you are committed to a relationship with the vendor. It is no less so when placing your existing tooling with a new metal stamping vendor. You need to assess their level of commitment. How invested are they into ensuring your tool is well maintained and stored? Do they require a certain production volume to justify maintaining and storing your tool? Can you meet and maintain those levels?

New tool. A badly built tool will make bad parts, regardless of where it is. So, if you are moving a tool because you are having quality issues, part of this move will require that the new vendor make modifications, repairs, or even completely re-tool it for you. Of course, you need to consider what it will cost to fix. Your concerns, especially if you are producing legacy parts with low production volumes, will extend to ROI—will it produce enough revenue to get your money back?

Expertise and capacity. Ask these questions to each new vendor you consider.

- Do you have the expertise or capacity to repair, rebuild, redesign, or re-tool, if necessary?

- Is it in-house or do you outsource?

- Can you troubleshoot the quality problems the tool may be creating?

- Can you repair and maintain that tool?

- What is the policy for fixing and repairing? Is it billable?

- Do you have sufficient press and production capacity to run the die and produce the quantities required?

Who owns the current tooling? Moving the tool may be necessary, and may require special consideration to release it from the current provider. You’ll need to resolve the following:

- Do you own the tooling?

- What does the tooling consist of? Is it permanent tooling or temporary, short-run tooling that requires re-tooling for every run?

- Will the current supplier release the tool to be relocated at a new supplier?

- Is there a fee? Most often, you’ve paid them to build the tool, though not always.

Reasonable expectations. Keep in mind that a reasonable expectation is that if you are supplying a tool, you can’t expect your vendor to rebuild it for free. Most places will have a tool maintenance department, though they may not be able to completely rebuild it. Often, companies have a small staff that maintains dies, but does not build them. If you are considering contracting them and agree what work goes into the tool, you need to find out ahead of time if they will take responsibility for the quality of the parts after the work is done. If they rebuild a major section to improve a quality problem, do they own it? The bottom line here: if you pay them to bring it to spec, make sure the scope of the work they do to fix or improve the tool is well-defined, so you know what they will take ownership of down the road.

3) What a New Tooling Vendor Needs to Know from You

Naturally, new suppliers will have questions for you. They will touch upon some of the same considerations you have for them. There is some standard information a new tooling vendor will ask you. They are going to need specifics about materials, consumption, and production expectations.

Current status. Prospective new vendors will ask if you need to move the tool. They will want to know if you own it.

Specifics. These details are vital to know, in some instances, if a partnership is a good fit—literally. Information you need to be ready to answer:

- Will it fit into their press?

- What material is needed?

- How many operations are needed to produce the part?

- Press operations, cleaning, deburring, finishing, etc.

- Is it a completed part right out of tooling?

Any good partnership begins with clear expectations, and answering all the concerns above will help you navigate through this process successfully from the start.

Time to Move Your Tooling?

If any of the discussion hits home for you, it may indicate that it is time to move your tooling. Larson works with customers at all levels of deep draw and precision metal stamping—from tooling to production. Through the years, we’ve created a process that helps customers move tooling and transition through to production seamlessly. The first piece in this process involves completing a tooling survey. This survey provides a new vendor with all the details of the stamping process necessary to accurately evaluate your tooling and process for manufacture in a new facility. Download it now.